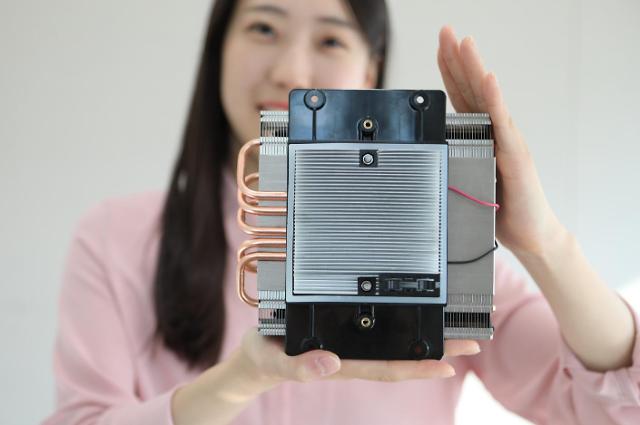

[Courtesy of UNIST]

Thermoelectric devices convert temperature differences to electric voltage and vice versa. Bulky and complex conventional thermoelectric generators are ideal for large facilities but they are not so cost-effective. Facilities that emit a huge amount of heat such as thermal power plants and steel mills could afford a thermoelectric device to recycle waste heat into electricity.

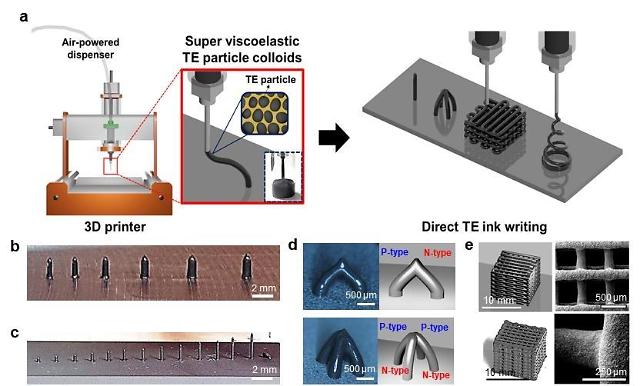

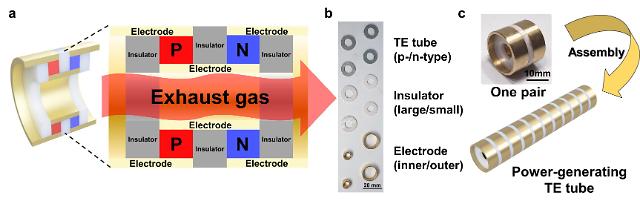

The Ulsan National Institute of Science and Technology (UNIST) said in a statement that its research team co-led by professors Chae Han-gi and Son Jae-sung has developed a thermoelectric technology to produce power-generating tubes using 3D printing techniques. Researchers found that the tube-shaped device is more effective than conventional devices.

"Through this research, we will be able to effectively convert heat generated by factory chimneys, the most common type of waste heat source, into electricity," Son was quoted as saying. He said that conventional thermoelectric devices were in rectangular parallelepiped shapes.

Researchers created the thermoelectric tube using a 3D printed ink made of lead (Pb) and tellurium (Te). Metal particles were mixed inside a glycerol solvent to provide viscoelasticity, a status that exhibits both viscous and elastic characteristics. The tube has a high thermoelectric performance at temperatures between 400 and 800 degrees Celsius, which is the temperature range of a car's exhaust gases. The tube shape makes it more effective in collecting heat than a conventional cuboid type.

"If we use 3D printing technology in the production of thermoelectric materials, we will be able to overcome limits of conventional materials," Chae said, adding that the new technology for providing viscoelastic characteristics to 3D printed materials will be used in various other sectors. UNIST's research was published by Advanced Energy Materials, an international scientific journal.