[Courtesy of Posco ICT]

Smart factories can produce products through an automated system through internet of things (IoT), artificial intelligence (AI) and big data. Factory operators favor the autonomous system because they can save operational costs and increase work efficiency. The popularization of smart factories has been accelerated by South Korea to increase work efficiency and reduce production costs. The Ministry of SMEs and Startups is planning to convert about 300,000 old manufacturing facilities into smart factories by 2022. According to global market research firm Markets and Markets, the domestic smart factory market is expected to reach $15.3 billion in 2024.

Posco ICT said in a statement on November 22 that the company won a contract to convert a steel-plate factory owned by Bn Group into a smart factory. Bn Group's factory is mainly used to produce surface-treated steel plates for home appliances, ships and construction. BN Group has 13 affiliates including companies specializing in shipbuilding equipment, liquor and venture investment. Posco ICT will collect and analyze operation data of Bn Group's steel plate factory and establish a smart factory system that can automatically manage major equipment. The information communication technology company will also develop a smart system called "Smart SMB Manufacturing Execution System" in which quality control and inventory management are integrated by 2022.

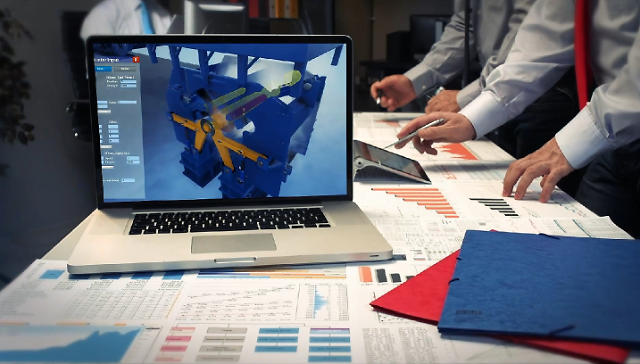

In March 2019, Posco ICT signed a cooperation agreement with Hyundai Robotics, a domestic industrial robot maker, to create a 3D simulation-based consulting and analysis service for smart factories that can predict and manage problems such as machine breakdowns. Posco ICT is in charge of the development and manufacturing of products, services and applications based on its own smart factory platform. Hyundai Robotics manages robot-based automated manufacturing analysis systems and facilities.